Robotic Surveying Outlines Its Place in Construction

Big names such as Skanska and HP are in on the trend — but a plucky little robot called the FieldPrinter might be in the lead

By Philip Russo August 20, 2024 9:00 am

reprints

Proptech has a snappy technology answer to snap lines.

The age-old method of multi-person crews laying out construction site dimensions by snapping chalk lines as part of the surveying process is being replaced by automated robots that are more efficient and at least as accurate, experts said.

As part of the equation, such robotic development in general is being shaped by skilled labor shortages and pricing, said Albert Zulps, national director of emerging technology at global construction giant Skanska.

“I’m pretty excited about the possibilities robotics have in construction, especially given some of the reports I’ve read on forecasted shortages of labor, especially in the surveying field,” said Zulps from his Boston office. “We have a lot of experience with robotics regionally, nationally and internationally. My perspective on robotics is that there are general robots, things like Spot, by Boston Dynamics, that can do a lot of different things, maybe not any one particularly well, but they’re very versatile. However, they’re also very, very expensive — basically, almost the price of a project engineer per year. So the value proposition of those could be tougher.

“And then there are these kinds of niche specialized robots more dedicated to a specific task. They do much better than a general robot would do. And the price is actually much more attractive as well.”

Skanska uses robots for specialized tasks such as taking 360-degree photos of projects, documenting work sites, bending rebar, and laying down brick, as well as surveying, said Zulps.

“We’re still figuring out the landscape,” he said. “There’s a lot of different considerations when you’re looking at doing a site survey, laying things out with a robot — efficiency, accuracy, and safety especially. What we’re excited about is redistributing the amount of effort that goes into something like layout in a more intelligent way, and taking the risk away from the teams doing layout. So people aren’t bending over and have blind spots when they’re hunched over snapping a line. They’re not always situationally aware. Having a robot do that work, those people still keep busy, but with more upfront planning of what they’re going to lay out.”

Zulps believes surveying robotics are steadily if unevenly growing in the construction industry.

“Right now it is really dependent on the project complexity and how the team works together, as well as proximity to the technology,” he said. “Perhaps as the industry starts seeing more examples of this working, we’re going to see rapid adoption.”

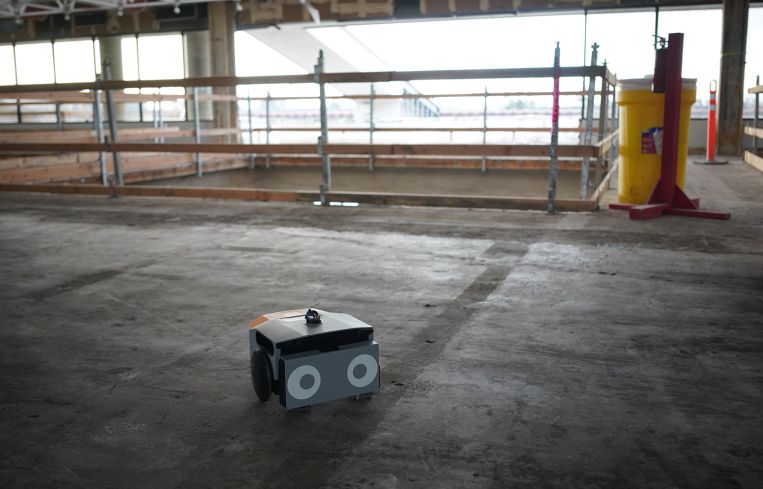

One of the proptech startups that Skanska uses on projects is Dusty Robotics, which claims to have pioneered automated layout in construction using a Roomba-like robot called the FieldPrinter.

Tessa Lau, CEO and co-founder of Dusty Robotics, explained that the company set out to update what’s been done in construction for the last 5,000 years.

“After you create a plan and a model of what you want to have built, the way the people in the field know what to do is that someone takes the plan, which is typically a set of drawings on a piece of paper, and they’re crawling around on their hands and knees using measuring tape and string to mark those plans out on the ground,” said Lau. “That process is called layout, and it’s typically done by professionally trained layout crews that are building off marks that are set out by surveyors, which are at known locations on the ground.

Dusty Robotics modernizes that process, which would’ve been familiar to the ancient Egyptians, Lau said.

“We create a robot that actually takes the digital building plans and uses surveyor technology to automate the process of marking those floor plans on the ground,” she said. “And that eliminates all the mistakes that happen when people are involved in doing the measurement and the marking. It also creates the opportunity to build buildings faster and at lower cost, with less human hurt in the process.”

The Dusty Robotics robot can also provide data to construction professionals on site, Lau said. Founded in April 2018, and headquartered in Mountain View, Calif., the startup won the 2024 Fast Company Most Innovative award in robotics.

“So, imagine a robotic vacuum cleaner with a printer strapped to it,” said Lau in explaining the FieldPrinter, currently in its second generation, with a third iteration to be released soon. “We built a little wheeled robot about one foot tall by two feet, and it drives around on the floor. On a freshly poured floor of concrete with no marks on it, our robot is the first thing to come onto that floor, and everywhere it goes it leaves a little trail of ink behind and marks out those plans on the floor.”

Another feature built into the robot over the last year is the ability to print QR codes on the floor, bringing additional information out to the field. “An electrician standing on this concrete slab scanning one of the QR codes that our system has printed can bring up a model,” she said. “Maybe it’s a 3D model of what he’s going to build, or maybe it’s the parts list of all the things that he needs to install.”

The robot is operated by one person on site, who can be trained in its use in as fast as a day, Lau said.

“When I first started the company I was worried that by building robots, we’re taking away jobs, and that we’re actually making it harder for people to be gainfully employed,” Lau said.

The opposite turned out to be true.

“And now the unions have gone on board, and they are actually teaching their members how to use Dusty robots,” Lau said. “We’ve actually partnered with the NorCal carpenters union, with the sheet metal union, Local 104 in our area, and those unions have created curriculums around teaching Dusty.”

That is leading to training in other parts of the U.S. via organized labor. “They’re really recognizing the fact that this is the future and they want to get behind the new technology and make that something that attracts more people to the industry, rather than have the philosophy that they’re going to prevent technology from entering their industry,” Lau said. “And I think that’s a great thing, both for us and for them.”

In addition, the technology provided by companies like Dusty Robotics is finding growing and more complex construction challenges. So far in North America, Lau said, the company has laid out more than 125 million square feet of buildings across a variety of projects.

“We follow the trends in the industry, and what we found is that the more complex projects are disproportionately adopting us,” Lau said. “That’s because a data center or a hospital, those are really complex jobs, and the amount of machinery that you have to fit into a very small space is very dense. So the layout matters a lot. If you’re off by an inch, then all the racks that you wanted to cram into your data center don’t fit.”

Along with the growth in artificial intelligence that is driving more power-draining data centers, Dusty Robotics is working on more hospital construction post-COVID, as well.

“There’s a lot more population growth in areas that weren’t set up with the right infrastructure, so there’s a lot of demand for the creation of medical facilities to help support that new population,” Lau said.

A third growth category of the moment for the company is manufacturing, particularly industrial automation. “If you order from Amazon and you get your delivery within two hours or the next day, imagine all the robots behind the scenes there that actually packed your box and shipped it,” she said. “Those facilities are making use of robotic automation, and the positioning of all of that automated machinery matters very precisely. So, we get called on to do a lot of those kinds of layout placements for those robotic systems.

Competition in this still small field of robotic layout and surveying is increasing, with Dusty Robotics rivals emerging from established tech companies like business hardware giant HP, said Lau.

“It’s a very healthy thing for the industry, because it means that bigger players are starting to take notice, and that normalizes and validates the space. So from our perspective, HP came on the market last year with their site print solution, and it’s not as good as ours. We’re still the market leader. But it’s nice to say that there’s a Fortune 500 vendor company that’s also playing in our space.

“One of the things we noticed was that after HP came on the market, our sales conversations got a lot easier, because before then there was some concern that maybe this is a new thing and it doesn’t work. You know, ‘You guys are just a startup. How long are you going to really be around?’ Then after HP came on the market, it became like, ‘Oh, OK. I guess this is a real thing. There’s a printer company that’s playing in this space.’”

Skanska’s Zulps agrees that reaction to and adoption of robotics for construction layouts and surveying is highly positive.

“It’s a different way of working, and we’re still figuring that out, but we’ve gotten some cool feedback,” said Zulps. “It does take more upfront preparation and projects might not be prepared for that. But we’ve got positive, ‘Wow, this thing really is accurate and we can trust it.’ So we’re in the process. And having said that, we exposed our company in Norway to some of the technology. They’ve embraced the technology, they’re able to take it and run, using several layout robots as we speak. They’re having a lot of success with that.”

Philip Russo can be reached at prusso@commercialobserver.com.